Print and Apply

Built for Easy Automatic Labeling Integration, Maintenance, and Operation

The pandemic expedited the transformation of automation, including print and apply, across industries. Automated labeling solutions replace manual workflow for better efficiency, to reduce high costs caused by human errors, and to increase 24/7 productivity. Automated print and apply systems are used in high volume applications on labels, cases, pallets, and others in logistics, manufacturing, pharmaceutical, as well as the food and beverage market sector.

Points to ConsiderWhy Choose UsPrint Engines & Modules Family Watch VideoSuccess Story

Points to Consider

To build a print and apply system, automatic labeling builders have to integrate a variety of elements together including PC/PLC controllers, scanners, conveyors, system hardware and software, and label design software, etc. Whether you plan to replace a current print engine or apply a new print engine system on production lines, there are three key points to consider before you choose the right one.

Compatibility

To synchronize with a systems PC’s or PLC’s to complete print jobs, print engines or print modules must be equipped with a GPIO interface, and support GPIO emulations and printer language firmware to simplify integration and migration efforts.

Reliability

Print engines or print modules—from components, mechanism design, to mean time between failures (MTBF) and more—must perform 24/7 to maximize uptime.

Applicable

Select a print engine or print module with the right system design for your applications and daily operations.

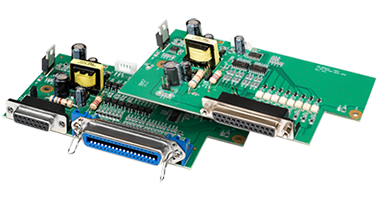

Why TSC Printronix Auto ID Print Engines & Modules?

Our print engines and modules are purpose-built for any print and apply system. It can be easily integrated to meet any application. The robust design can withstand harsh environments and ensure performance for years to come.

Print Engines and Modules Family

The below table will help you quickly identify the right print engine or print module for your application needs. The full-functionality print engine is designed to reduce development efforts and time to market. The cost-effective print module offers maximum flexibility and helps label applicator builders to fulfill their unique designs.

| Print Engines | Print Modules | ||||

|  |  |  |  | |

| Model | PEX-2000 6-inch | PEX-2000 4-inch | PEX-1001 4-inch | MH Series 4-inch | MB Series 4-inch |

| Media Width | 50.8mm -180mm (2" - 7.1") | 16mm - 118mm (0.63" - 4.65") | 20mm - 114mm (0.8" - 4.5") | 20mm - 114mm (0.8" - 4.5") | 20mm - 120mm (0.8" - 4.7") |

| Print Resolution | 203, 300 dpi | 203, 300, 600 dpi | 203, 300, 600 dpi | 203, 300, 600 dpi | 203, 300 dpi |

| Max. Print Speed | 14 ips | 18 ips | 18 ips | 14 ips | 12 ips |

| Min. Label Length (peel-off) | 25.4mm | 5mm | 5mm | 12.7mm | 25.4mm |

| Display | Color | Color | Color | Color touch | Color touch |

| Top Black Mark Sensor | Yes | Yes | Yes | Yes | -- |

| Applicator Interface | GPIO (DB15F) | GPIO (DB15F) | GPIO (DB15F) | GPIO (DB15F) | GPIO (DB15F) |

| Option |

|

|

|

|

|

| Printer Management Tools | SOTI Connect, TSC Console | SOTI Connect, TSC Console | SOTI Connect, TSC Console | SOTI Connect, TSC Console | TSC Console |

Print Engine Expedited e-Commerce Fulfillment with Label Automation

A China-based systems integrator (SI) specialist in print and apply solutions was tasked with helping its customer, a shoe manufacturer, to expand labeling to 30,000 per day for faster delivery to meet a surge in sales. Learn how our print engine helped the SI meet the shoemaker’s requirements.