6-inch PEX-Series High Performance Print Engine.

The 6-inch PEX-2000 Print Engine easily integrate into any label applicator for smooth daily operation, reducing integration efforts and speeding up time-to-market.

Industries and Applications

The PEX-2000 is highly compatible with hardware and software for easy integration. It supports DB 15 and DB 25 interface and major print brands GPIO emulator the customizable printer language firmware supports major printer languages so template commands and print files can remain the same.

The PEX-2000 is reliable for 24/7 operations, compact to meet space constraints, and it’s easy to service. From its angle-adjustable peel-off module, advanced, sensory design, and to optional RFID, the PX-2000 provides precision functionality and future-prove technology. It’s also compatible with the remote printer management tools, TSC consult and SOTI connect.

Highly Compatible with Label Applicator Integration

- With a 14% smaller rear section, the compact footprint makes it easy to maintain and mount to label applicators in any orientation.

- Supports both 25-pin and 15-pin D-Sub socket connectors and major printer brands’ GPIO emulations, making integration and replacement easy.

- Customizable printer language firmware supports major printer languages, eliminating the need to redesign your template commands or print files.

Advanced Performance to Meet Diverse Applications

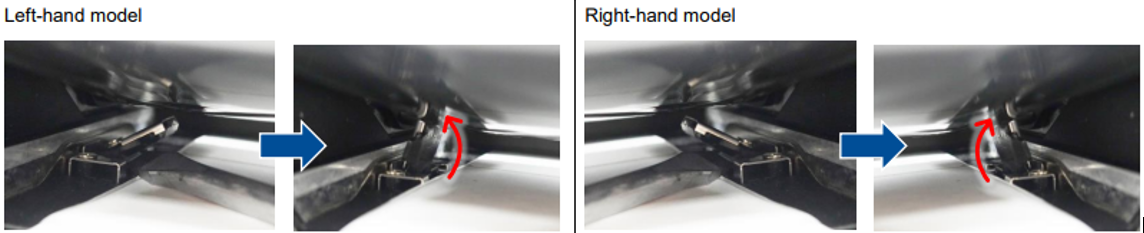

- Industry-first adjustable peel-off module in metal supports performance in angles of minus 18-degrees to minus 3-degrees peel off. This flexibility makes applicator integration and scaling up applications easy.

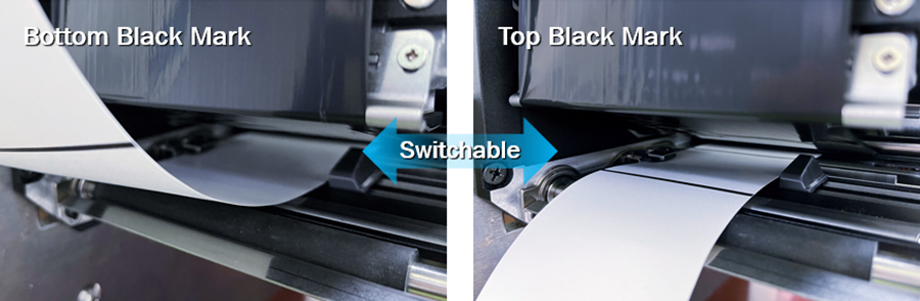

- The top black mark sensor supports labels with the black mark on the print side, e.g. preprinted labels.

- The optional RFID encoding module supports emerging applications, such as item-level RFID labeling in apparel. Long distance back-feed enables overstriking bad RFID labels.

Reliable Design to Maximize Uptime

- Full metal chassis is robust to withstand harsh environments.

- Mean time between failures (MTBF) is up to 22,000 hours for 24/7 mission-critical operations.

- A magnetic lock tightly seals the media door under any vibration in any orientation.

Mechanism Design for Smooth Operations

- The PEX-2000 media sensors were designed to make media handling and calibration easy with top and bottom sensors. Both sensors can be adjusted to different locations to support various media type setup and calibration. Additionally, the rear label holder cover is simple to release, giving users more space to clean sensors.

- Wide media handling space makes media installation easier (55mm max.).

- One push and quick release design makes removal of the printhead and its replacement effortless.

- After being installed on any label applicator, the rear chassis can be easily lifted and pulled out in two steps, saving valuable space for repairs and component replacement without taking up additional room on the shop floor.

Remote Management and Monitoring Ensure Print Engine Serviceability

- Through the internet, the web-based SOTI Connect remote printer management software offers one dashboard for deployment and real-time monitoring of all print engines. IT staff can set up, configure, and update print engines from a single console. Users can also set up rules in the console so that when pre-defined conditions are met, notifications will be sent so that relevant stakeholders can take corresponding actions.

- Within the intranet, the on-premise TSC Console remote printer management software enables IT staff to deploy, manage, monitor, and troubleshoot through wired or wireless connections to one or a group of print engines. This ensures that print engines are serviceable at all times. With TSC Sense Care, the TSC Console can monitor TPHs, and track and record the TPH odometer for component replacement.

- 203 dpi (8 dots/mm)203 dpi (8 dots/mm)300 dpi (12 dots/mm)300 dpi (12 dots/mm)

- Direct thermal/Thermal transferDirect thermal/Thermal transferDirect thermal/Thermal transferDirect thermal/Thermal transfer

- Color LCD touchscreen with buttonsColor LCD with buttonsColor LCD with buttonsColor LCD with buttons

- Parallel Port

Ethernet

GPIO

Serial RS-232

USB

USB HostParallel Port

Ethernet

GPIO

Serial RS-232

USB

USB HostParallel Port

Ethernet

GPIO

Serial RS-232

USB

USB HostParallel Port

Ethernet

GPIO

Serial RS-232

USB

USB Host - Wi-Fi with BluetoothWi-Fi with BluetoothWi-Fi with BluetoothWi-Fi with Bluetooth

- TSC Console

SOTI Connect (license required)TSC Console

SOTI Connect (license required)TSC Console

SOTI Connect (license required)TSC Console

SOTI Connect (license required) - Print enginePrint enginePrint enginePrint engine

- 356mm (14”)/second356mm (14”)/second305mm (12”)/second305mm (12”)/second

- 168 mm (6.61”)168 mm (6.61”)168 mm (6.61”)168 mm (6.61”)

- 14,732mm (580“)14,732mm (580“)6,604mm (260“)6,604mm (260“)

- 512MB DDR2 RAM memory512MB DDR2 RAM memory512MB DDR2 RAM memory512MB DDR2 RAM memory

- 512MB Flash memory512MB Flash memory512MB Flash memory512MB Flash memory

- 180mm (7.09“)180mm (7.09“)180mm (7.09“)180mm (7.09“)

- Continuous, die-cut, black mark, fan-fold, notchContinuous, die-cut, black mark, fan-fold, notchContinuous, die-cut, black mark, fan-fold, notchContinuous, die-cut, black mark, fan-fold, notch

- 600m600m600m600m

- 180mm (7.1")180mm (7.1")180mm (7.1")180mm (7.1")

- Die-cast based print mechanismDie-cast based print mechanismDie-cast based print mechanismDie-cast based print mechanism

- TSPL-EZDTSPL-EZDTSPL-EZDTSPL-EZD

{[{ key }]}

Yes, you can clone the printer's configuration, firmware or upload label style to a USB flash drive and specify the file name inside. Please contact the TSC Service Center for more information.

To customize the logo, contact TSC for more information.

If you want to print with labels that have black marks on the print side, go to Sensor > Black Mark Location and then select Print Side. After finishing the setting, follow the steps described in the User Manual to adjust the position of the top black mark sensor. Please refer to the PEX-2000 User Manual for more information.

Yes. You can easily access the media drive module by just opening the rear cover. You can choose to replace the whole module or only the belt. The replacement takes no more than 15 minutes.

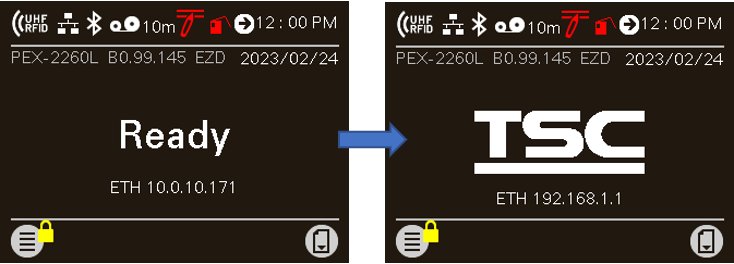

Yes, users are allowed to rotate the printer's display. The display can be set to 0 degrees (standard) or 180 degrees using the printer's setup menu. To change the direction of the display, go to Menu > Advance > LCD Invert and then select Yes or No based on how you are going to use the printer.

Yes. You can establish rules using TSC Console Web so that your printer will execute what you have set up every time a condition is met. Conditions for a rule can be time-based or event-driven.

You can set your printer to take an activity daily, weekly, monthly, or at a particular date/time.

Yes, TSC Console Web enables users to update printer firmware remotely.

Yes, TSC Console Web allows users to set up a reminder for printhead maintenance and the printhead mileage can be displayed on the dashboard.

No. TSC Console Web must be used through either a wireless or wired network. That is to say your printer must support either Wi-Fi or Ethernet interface if you want to manage the printer using TSC Console Web.

Both ports do not interfere with each other. They can work simultaneously.

Yes, you can use the front gap sensor to calibrate the micro label. The printer's default gap media sensor setting is on the label holder cover (rear side of the printer), with the green media sensor LED. If you want to use the front gap sensor, go to Sensor > Gap Location and then select Front. You can refer to the PEX-2000 User Manual for more information.

Yes. To install the thick media (0.9 mm - 1.2 mm), use a tool to lift up the front gap media sensor to facilitate the media installation.

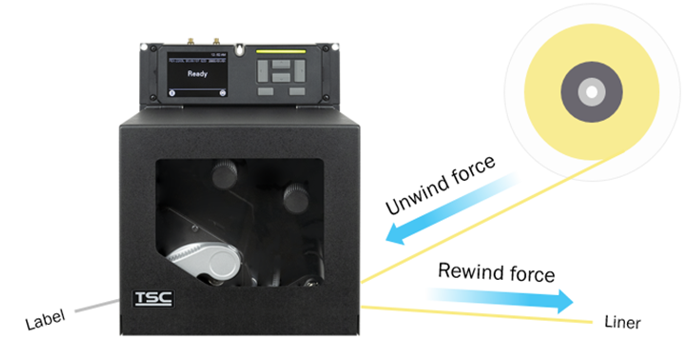

Media Unwind Force:

- In Peel Mode (with liner drawn by the peel roller):

Applicator media supply steady state tension must be uniform and not exceed 940g (2.0 lbs.) Start/Stop tension transients must not exceed 1840g (4.0 lbs). - In Tear Mode (media feed without peeling):

Media tension not exceed 400g (0.88 lb).

Media Rewind Force:

- In Peel Mode (with liner drawn by the peel roller):

Applicator media take-up pull tension must be uniform and not exceed 1840g (4.0 lbs).

Users are allowed to save up to 5 sets of different configuration for quick deployment.

The compatible architecture for TSC Console Web is x86_64 only and the Linux OS distribution is Ubuntu 22.04 or above.

Currently the supported RFID functions through TSC Console Web are: Calibration, Read, and Write.

The UI for TSC Console Web is available in English, Traditional Chinese, Simplified Chinese, German, Danish, Spanish, Finnish, French, Italian, Japanese, Korean, Dutch, Norwegian, Portuguese, and Swedish.

The management commands are transmitted/received through port 3007.

GPIO (DB25F) compatible with the PEX-2000 Series.

- PEX-1121

- PEX-1131

- PEX-1161

- PEX-1221

- PEX-1231

- PEX-1261

- PEX-2260R

- PEX-2260L

- PEX-2360R

- PEX-2360L

- PEX-2240R

- PEX-2240L

Internal Wi-Fi with Bluetooth combo module compatible with the PEX-2000 6-inch Series.

- PEX-1121

- PEX-1131

- PEX-1161

- PEX-1221

- PEX-1231

- PEX-1261

- PEX-2260L

- PEX-2360L

- PEX-2260R

- PEX-2360R

- PEX-2240L

- PEX-2240R