Welcome to Our Blog

Get the latest information on new products and solutions, trending industry topics, best practices, tips and tricks, and much more.

Automotive

1429

/en/blog/automotive

Barcode Inspection

418

/en/blog/barcode-inspection

Cannabis

1430

/en/blog/cannabis

Company News

415

/en/taxonomy/term/415

Cybersecurity

1463

/en/blog/cybersecurity

Events and Tradeshows

1421

/en/blog/events-and-tradeshows

Food & Beverage

1426

/en/blog/food-beverage

Healthcare

1425

/en/blog/healthcare

High Resolution

414

/en/blog/high-resolution

Industry Trends

1419

/en/blog/industry-trends

Manufacturing

1424

/en/blog/manufacturing

Mobile Printing

1420

/en/blog/mobile-printing

Partner Perspectives

1460

/en/blog/partner-perspectives

Remote Printer Management

1432

/en/blog/remote-printer-management

Retail

1423

/en/blog/retail

RFID

416

/en/blog/rfid

Software Solutions

1433

/en/blog/software-solutions

Standalone

419

/en/blog/standalone

Supplies

417

/en/taxonomy/term/417

Supply Chain

1461

/en/blog/supply-chain

Tips & Best Practices

1431

/en/blog/tips-best-practices

Transportation & Logistics

1422

/en/blog/transportation-logistics

Warehouse & Fulfillment

1427

/en/blog/warehouse-fulfillment

Warehouse and logistics are the hidden success behind nearly every business operation, ensuring items move through the supply chain at the right place and time. Speed and efficiency are critical in these industries, and labeling is no exception. Labeling is essential in item, box, and pallet tracking. The key is performing this action quickly and efficiently.

The retail industry plays an integral role in our daily lives, encompassing everything from buying clothing and groceries to ordering take-out meals, all of which involve labels. Labeling can be very demanding for the retail sector. In the modern-day retail world, there is a wide variety of labels that require flexibility to adapt to the industry's diverse applications.

Businesses today actively seek ways to minimize their environmental impact and enhance workplace safety. One effective approach is transitioning from traditional labels to linerless labels. This transition not only reduces environmental impact but also aligns seamlessly with regulatory compliance, significantly enhancing operational efficiency.

Sustainability has emerged as a pivotal factor across numerous industries, driven by environmental protection and shifting consumer tastes.

As the world economy has decelerated since 2021, job markets in OECD countries remain strained. Despite employment rates returning to pre-pandemic levels and unemployment rates hitting their lowest since the early 1970s, a stark labor shortage persists due to a lack of qualified talent, highlighting a supply-demand imbalance.

Increasing demand for industrial printers is propelled by automation in manufacturing, traceability regulations in the food and beverage sector, hybrid retail strategies, e-commerce-driven logistics growth, and a heightened safety emphasis in healthcare, according to VDC Research.

Since 2002, we have grown from a modest sales revenue of 2 million RMB to an impressive 100 million RMB, becoming the leading distributor for TSC Auto ID in mainland China. This growth is a testament to our dedication to brand advocacy, market penetration, and customer service.

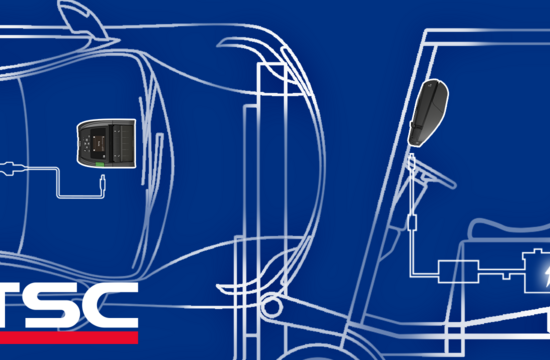

To keep your mobile printing operation running smoothly, no matter where the road takes you, the power supply must be reliable and rugged. That's why we're excited to announce the launch of two new mobile power adapters designed specifically for charging mobile printers in vehicles, including increased power for diverse fleets.

Since the beginning my journey in this industry as a technician in 1997, my passion for innovation and customer-centric solutions led me to establish Shanghai Lepei in 2009. Specializing in printer applications and consumables, Lepei initially catered to end users, offering comprehensive solutions tailored to their needs.

In today's fast-paced business environment, mobile printing solutions are becoming increasingly essential for field workers across various industries. However, ensuring these printers are secure and functional within the confines of different work vehicles can pose a challenge. TSC Auto ID, a leading innovator in barcode and label printing solutions, has introduced two new mobile printer accessories designed to enhance usability and flexibility: the Quick Release Vehicle Mount Kit and the Fanfold Media Holder.