7 Reasons Why On-Metal RFID Tags Can Be Ideal for Asset Tracking

The world of asset tracking is constantly evolving, and RFID (Radio-Frequency Identification) technology is leading the charge. While traditional RFID tags have served us well, there's a new breed specifically designed for a specific challenge: metal surfaces.

On-metal RFID tags are game-changers, offering unparalleled performance and versatility in even the most challenging environments. Whether you're managing a bustling repair facility, a high-tech IT department, or a rugged industrial factory, here are 7 reasons why on-metal RFID tags can serve you well for tagging difficult-to-read items:

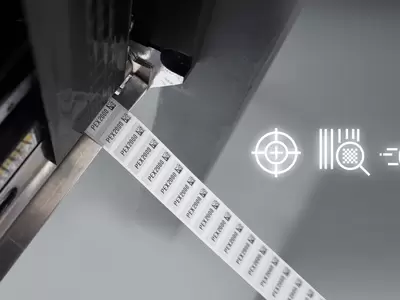

1. Printable Power:

On-metal RFID tags can be printed directly on-site, on-demand using specialized printers. This means you can customize your tags with logos, barcodes, or even serial numbers, creating a one-stop solution for identification and tracking. Plus, TSC industrial printers print up to 600 dpi for small labels.

2. Encoded Excellence:

Depending on chip memory, on-metal RFID tags can be encoded with a wealth of information for environments that do not support a quick or reliable connection to a database. Embed details like part numbers, maintenance schedules, or even environmental data, and unlock a whole new level of asset management sophistication down to the item level.

3. Flexibility For the Win:

Metal surfaces come in all shapes and sizes, and your tags need to adapt. On-metal RFID tags are tested for flexibility and curvature, allowing placement on uneven surfaces with ease. No more struggling with ill-fitting tags that fall off or fail to read.

Can’t wait? For Sales assistance, please click here.

4. Sticky & Savvy:

On-metal RFID tags can even be ordered with removable adhesive, making them easy to attach and remove without leaving a trace. Perfect for situations where temporary auto ID tracking is needed like in an automotive assembly line.

5. Durability That Reigns Supreme:

Workplace environments can be harsh, but highly durable on-metal RFID tags are available. They're crafted with rugged materials and advanced technology to withstand extreme temperatures, chemicals, moisture, and even physical challenges such as abrasion. Invest in tags that can survive your environment. For example, on-metal tags for tools used at a remote worksite may need to withstand the harsh outdoor elements, including extreme heat or cold, sunlight, rain and dust.

6. Versatility Unbound:

The applications for on-metal RFID tags are endless. Track tools and equipment in factories, monitor IT assets in data centers, manage shipping containers in ports, or even keep tabs on valuable medical devices. The possibilities are truly limitless.

Limitless you say? How about automation? Yes, we can do that. Click here to read about automating RFID Tagging with the PEX2000 print engine, one of the industry’s most versatile print engines, which can also work with on-metal tags.

7. Standard Setting Performance:

Don't settle for subpar performance. On-metal RFID tags are highly engineered, ensuring reliable read ranges and seamless integration with existing RFID infrastructure. Invest in quality that won't let you down.

With on-metal RFID tags, you're not just upgrading your asset tracking system, you're revolutionizing it with the capability to tag most if not all your assets. Experience the power of enhanced visibility, streamlined processes, and improved efficiency. Your business, warehouse, or IT department will thank you for it.

So, if you are constrained by the limitations of traditional tags, embrace on-metal RFID technology to tag difficult-to-read items. Remember, in the world of asset management, it's not just about putting an RFID tag on an item – you need to be able to read the tag. And with on-metal RFID tags, the possibilities are nearly limitless. In fact, on-metal RFD tags can be printed up to 2mm of thickness, opening potentially more affordable and versatile options for asset tracking in many scenarios. For example, in the automotive industry, on-metal RFID tags are used to track parts during vehicle production.

Want to dive deeper?

Visit our RFID blog library to learn all things RFID. Or, check out this webinar featuring TSC’s RFID subject matter expert, Chris Brown as he demystifies how our RFID can easily improve your asset tracking processes.

For Sales assistance, please click here.