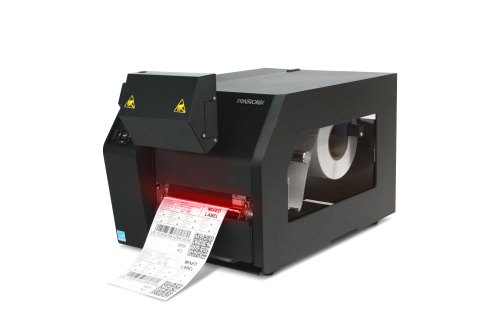

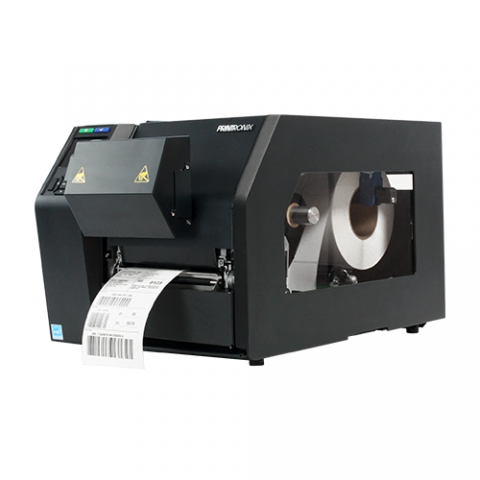

T8000 Series 6-Inch Enterprise Industrial ODV-2D Printers

Our most versatile 24/7/365 printer with 6-inch print width, the T8000 Series features color display, multi-connectivity capability with optional ODV-2D inline barcode verifier technology.

Industries and Applications

The T8000 is the premier high-end thermal printer. With unmatched industrial performance, ease of use, and 100% verifiable output, the T8000 exceeds the requirements of the most demanding mission critical manufacturing and distribution operations.

ODV-2D is the industry’s leading affordable, fully integrated solution with the ability to print, verify and validate 1D and 2D barcodes.

Built on the robust T8000 printer platform, ODV-2D includes an integrated verifier that grades barcodes to ISO standards and stores a detailed report of each transaction. Our exclusive technology reads each barcode, overstrikes the entire label of a rejected barcode, and reprints a new label.

Key features:

- The ODV-2D is a fully integrated barcode inspection system

- Automatically finds, reads, grades, and reports results for every barcode on every label

- Works with all major thermal printer languages, as well as Postscript and PDF

- Automatically overstrikes and reprints any label with missing or low-quality barcodes

- Easy settings for threshold grade level and recovery actions

- 203 dpi (8 dots/mm)300 dpi (12 dots/mm)

- Direct thermal/Thermal transferDirect thermal/Thermal transfer

- Color LCD with buttonsColor LCD with buttons

- Ethernet

GPIO

Parallel port

Serial RS-232

USBEthernet

GPIO

Parallel port

Serial RS-232

USB - Wi-FiWi-Fi

- PrintNet Enterprise

SOTI Connect (license required)PrintNet Enterprise

SOTI Connect (license required) - VerifierVerifier

- 8 ips (203.2 mm/s) @ 200 dpi, 8 ips (203.2 mm/s) @ 300 dpi8 ips (203.2 mm/s) @ 200 dpi, 8 ips (203.2 mm/s) @ 300 dpi

- 4.1" (104mm)4.1" (104mm)

- 512 MB RAM512 MB RAM

- 128 MB128 MB

- Full-Cut; Patrial-Cut; High-Speed; GarmentFull-Cut; Patrial-Cut; High-Speed; Garment

- 4.5" (114.3 mm)4.5" (114.3 mm)

- Gap; Mark; Advanced Gap; Advanced NotchGap; Mark; Advanced Gap; Advanced Notch

- 625 Meters625 Meters

- 1.5" to 3.0" (37.5 - 76 mm)1.5" to 3.0" (37.5 - 76 mm)

- 0.25"(6.35 mm)/1.0"(25.4 mm) continuous/tear-off; 0.5"(12.7 mm) peel-off0.25"(6.35 mm)/1.0"(25.4 mm) continuous/tear-off; 0.5"(12.7 mm) peel-off

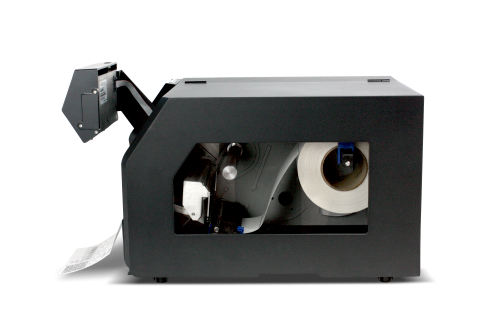

- Die-cast aluminum frame and print mechanism; steel cover; large clear media view windowDie-cast aluminum frame and print mechanism; steel cover; large clear media view window

- Most Major Printer LanguagesMost Major Printer Languages

{[{ key }]}

Yes. You can establish rules using TSC Console Web so that your printer will execute what you have set up every time a condition is met. Conditions for a rule can be time-based or event-driven.

You can set your printer to take an activity daily, weekly, monthly, or at a particular date/time.

Yes, the printheads are user replaceable and will automatically detect and accept when a user has changed from a 203 to a 300 dpi or vice-versa.

Yes, TSC Console Web enables users to update printer firmware remotely.

Yes, TSC Console Web allows users to set up a reminder for printhead maintenance and the printhead mileage can be displayed on the dashboard.

Yes, the ODV-2D is available as a field kit and can be added to any 4-inch T8000 and T6000e printer. Only ODV-2D Certified Partners can purchase and install an ODV-2D field kit.

Yes, the ODV-2D can handle both 1D and 2D barcodes in any orientation, including picket fence and ladder barcodes. Some 2D barcodes may not be available at launch.

No. TSC Console Web must be used through either a wireless or wired network. That is to say your printer must support either Wi-Fi or Ethernet interface if you want to manage the printer using TSC Console Web.

No tools are required.

Both ports do not interfere with each other. They can work simultaneously.

No, the throughput speeds of the ODV-2D are highly dependent upon the setup and validation procedure options that are selected by the operator. In addition, label formats that have numerous barcodes with large data validation requirements will impact throughput speeds. However, the simplicity of setup, and operation of the ODV-2D provides significant advantages in the majority of applications. As a result, throughput speeds have not been an issue with initial installations. The Printronix Auto ID VAR partner is capable of evaluating your application to ensure that throughput speeds are optimized to meet your requirements.

The ODV-2D both verifies and validates barcodes as they are printed. The data printed on the label is validated to match the data sent from the host. The barcode is verified to comply with ISO standards.

The ODV-2D both verifies and validates barcodes as they are printed. The data printed on the label is validated to match the data sent from the host. The barcode is verified to comply with ISO standards.

Calibration is described in the Control Panel Printer Setup Wizard. Also, under the Settings menu you select the Gap/Mark sensor that matches the type of media installed and then select the Auto Calibrate option. In addition, you can set the printer to do an Auto Calibrate at power up and/or when the pivoting deck is opened and then closed. In all cases the printer will advance a few labels and calibrate the sensors so that they will detect TOF.

The T8000 icon-based control panel will guide you through the changes of configuration and settings of the printer. With the user-friendly step-by-step setup wizard, you can manage the printer settings easily. If you need more information, please refer to the User Manual.

Users are allowed to save up to 5 sets of different configuration for quick deployment.

To more closely monitor the installation of ODV-2D technology, units will only be available through our Value Added Resellers who have been ODV-2D Certified.

Yes. ODV-2D is fully integrated into the same footprint as the printer and is tied to the printer controller so data from the application can be passed to ODV-2D, the printer can overstrike and reprint a failed label without operator intervention, and the data from ODV-2D can be integrated into Print Network Enterprises reporting and monitoring capabilities.

Yes, the many advantages of 802.11ac functionality are available in the T8000 and T6000 models of printers. Typical W-Fi speeds are expected to improve 3x to 5x over older W-Fi versions.

The compatible architecture for TSC Console Web is x86_64 only and the Linux OS distribution is Ubuntu 22.04 or above.

Currently the supported RFID functions through TSC Console Web are: Calibration, Read, and Write.

The UI for TSC Console Web is available in English, Traditional Chinese, Simplified Chinese, German, Danish, Spanish, Finnish, French, Italian, Japanese, Korean, Dutch, Norwegian, Portuguese, and Swedish.

The major benefit of having a PostScript/PDF printer command language is the ability to affordably and easily replace costly laser printers.

The management commands are transmitted/received through port 3007.

No, the ODV-2D comes either pre-installed at the factory or included in the printer carton for installation at the site. We still require reseller certification to enhance the ability of the reseller to provide assistance with any calibration or validation questions.